Call Anytime

08045801042

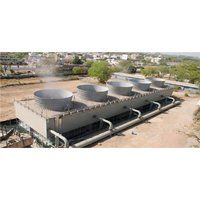

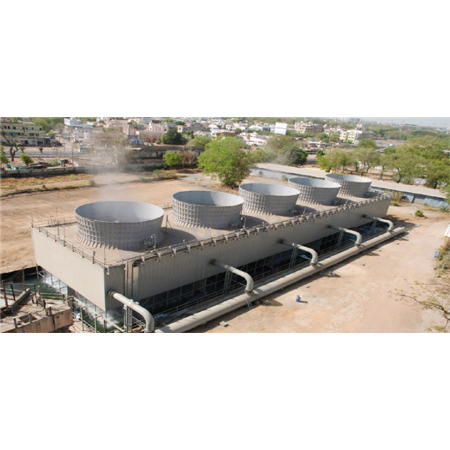

Cooling Tower Plant

Product Details:

- Air Flow 35000 CFM (Cubic Feet per Minute)

- Application Industrial process cooling, HVAC, Power plants, Chemical industries

- Refrigerating Capacity Not Directly Applicable (Typically measured in TR or kW for chillers)

- Motor 7.5 HP Three Phase Electric Motor

- Material FRP (Fibre Reinforced Plastic) Body with Stainless Steel Hardware

- Condition New

- Type Induced Draft Cooling Tower

- Click to view more

Cooling Tower Plant Price And Quantity

- 20000 INR/Piece

- 1 Piece

- Less than 0.02% of Circulating Water

- 1200 mm

- Sky Blue/Grey (Customizable)

- Flanged Connection

- Hot Dip Galvanized Steel

- Honeycomb PVC Fill

- Outdoor

- Single / Multiple as per Requirement

- Minimal, Easy Access Panels

- Axial Flow Fan

- Up to 15 Years with Proper Maintenance

Cooling Tower Plant Product Specifications

- Wet Cooling / Evaporative

- 35000 CFM (Cubic Feet per Minute)

- 3 Phase, 50 Hz AC

- Not Directly Applicable (Typically measured in TR or kW for chillers)

- Industrial process cooling, HVAC, Power plants, Chemical industries

- New

- 200 m/hr

- Low Noise Fan Design, Noise Level < 70 dB(A)

- 415 V

- 7.5 HP Three Phase Electric Motor

- Induced Draft Cooling Tower

- PVC, SS 304

- ABS / PP (Polypropylene)

- 10 HP ISI Certified Electric Pump

- FRP (Fibre Reinforced Plastic) Body with Stainless Steel Hardware

- Not Applicable or External (Cooling Tower Systems typically use pumps, not compressors)

- 2400 mm x 1500 mm x 3500 mm

- Less than 0.02% of Circulating Water

- 1200 mm

- Sky Blue/Grey (Customizable)

- Flanged Connection

- Hot Dip Galvanized Steel

- Honeycomb PVC Fill

- Outdoor

- Single / Multiple as per Requirement

- Minimal, Easy Access Panels

- Axial Flow Fan

- Up to 15 Years with Proper Maintenance

Cooling Tower Plant Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque, Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C)

- 10 Piece Per Week

- 10 Years

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

High grade Cooling Tower is being provided by us in wide range. This tower is widely applicable for various industries and sectors like petroleum, power plants, oil refineries, food processing and so on in order to remove the heat absorbed in this tower. Furthermore, there are miscellaneous countenance of Cooling Tower which includes easy installation, anti-corrosive nature, low maintenance, longer working life, high strength, trouble-free performance, optimum capacity, smooth surface, excellent functionality and many more. Apart from this, the provided product can be accessed in various colors, sizes, dimension and at feasible prices as per the demands and requirements of the customers.

FAQs:

Q: What is a cooling tower?

A:A cooling tower is a device used to reject heat from a water-cooled system to the atmosphere. It works by evaporating a portion of the water being cooled, which reduces the temperature of the remaining water and takes away the heat.

Q: What are the different types of cooling towers?

A: There are two main types of cooling towers: natural draft and mechanical draft. Natural draft cooling towers rely on wind to move air through the tower, while mechanical draft cooling towers use fans to circulate air. Within the mechanical draft category, there are several sub-types, including induced draft, forced draft, and counterflow cooling towers.

Q: What are the benefits of using a cooling tower?

A: Cooling towers offer a number of benefits, including energy efficiency, water conservation, and improved system performance. They can also help reduce the overall cost of cooling by reducing the amount of energy required to cool water and by reusing water multiple times.

Q: How does a cooling tower work?

A: cooling tower works by passing hot water through the tower, where it is exposed to air. The air cools the water and some of it evaporates, which removes heat from the system. The cooled water is then returned to the system to be reused.

Reliable Industrial Cooling Solution

With advanced axial flow fan technology and honeycomb PVC filling, this cooling tower is engineered to support industrial operations, power plants, chemical industries, and commercial HVAC applications. The system guarantees efficient heat rejection, stable performance, and adaptability for various process cooling needs, offering a dependable choice for large-scale installations.

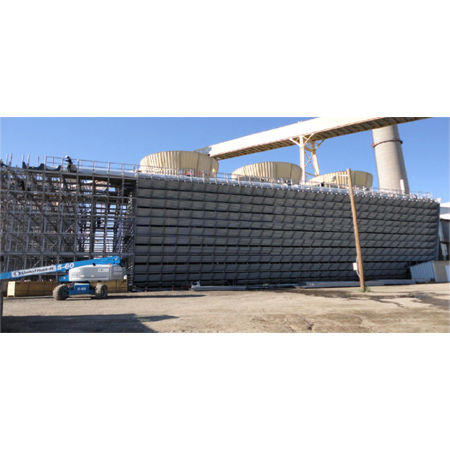

Robust Construction and Enhanced Durability

Constructed with a durable FRP body and hot dip galvanized steel structure, this cooling tower ensures structural integrity and long service lifeup to 15 years with proper maintenance. Stainless steel hardware and high-quality components provide resistance to corrosion, weathering, and chemical exposure, making it optimal for challenging outdoor environments.

Minimal Maintenance and Easy Access

Designed with user convenience in mind, this cooling tower features easy access panels and minimal maintenance requirements. The system supports quick inspections and troubleshooting, with hassle-free replacement of fill media or nozzles. Low drift loss and noise control features further enhance operational effectiveness and workplace comfort.

FAQs of Cooling Tower Plant:

Q: How does the axial flow fan improve the cooling towers efficiency?

A: The axial flow fan, with a 1200 mm diameter, delivers high airflow (35,000 CFM) that increases heat rejection efficiency while maintaining low energy consumption, making it ideal for industrial process cooling and HVAC applications.Q: What is the benefit of using honeycomb PVC fill media in the cooling tower?

A: Honeycomb PVC fill media provides a large surface area for water and air contact, maximizing heat exchange and improving cooling tower efficiency while ensuring minimal drift loss and reliable performance over extended periods.Q: Where can this cooling tower plant be installed?

A: This cooling tower is designed for outdoor installation in industrial facilities, power plants, and chemical plants. Its robust FRP body and hot dip galvanized steel frame withstand diverse environmental conditions commonly found in such locations.Q: What is the process for maintaining this cooling tower plant?

A: Routine maintenance involves periodic inspections, cleaning of filling media, and checking for leaks. Easy access panels facilitate quick servicing while the minimal maintenance design ensures that only basic checks are typically required to keep the system running efficiently.Q: When should multiple cells be considered for this cooling tower?

A: Multiple cells are recommended for larger facilities that require higher cooling capacity or need redundancy for continuous operation. The modular design accommodates both single and multiple cell configurations as per specific process and site requirements.Q: What are the main benefits of a low-noise fan design in this cooling tower?

A: The low-noise axial fan ensures the cooling tower operates at sound levels below 70 dB(A), promoting a quieter work environment and making the installation suitable for noise-sensitive industrial or commercial locations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+